Authors: Carola Coninx, Lina Hansen, Lukas Heitmann, Maja Roos, Niklas Wölfer

Last updated: December 29, 2022

1 Definition and relevance

Climate protection and environmental protection are becoming increasingly important issues, especially in today’s economy. Consequently, companies are being called upon to take decisive measures to reduce their environmental impact, particularly in connection with the manufacture and consumption of products, to keep up with the competition in climate policy. Life cycle assessment (LCA) represents a suitable method with which such an environmental assessment can be carried out.1EN ISO 14044:2006 (D/E).

In a nutshell, the LCA exists to measure the environmental impact of a product or a service (for brevity sometimes referred to just as a product) on the world.2Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. When analyzing the entire footprint, not just of a single product, but of an entire system that is composed of the individual processes of the product’s life cycle, numerous factors play a role.3Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH. Questions such as “What raw materials were involved in the production process and where do they come from? How are my goods produced?” and “How were the goods transported?” may arise, for example.

Today, LCA is a method defined by the International Organization for Standardization (ISO) 14040:2006 and 14044:2006 for analyzing the environmental aspects and effects of product systems.4Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH. The International Organization for Standardization (ISO) is a renowned, international, independent, non-governmental organization made up of experts that sets international standards and whose standards are highly regarded due to partnerships with 167 countries.5International Organization for Standardization, About us. Available at https://www.iso.org/about-us.html (2022). LCA, therefore, provides a framework and defines several stages to measure the impact on all life cycle stages and further facilitate decision-making and make products more sustainable.6EN ISO 14044:2006 (D/E).

According to ISO 14044:2006, LCA is relevant for different instances and can be used by several departments within a company. The LCA is suitable to show that certain regulations are complied with, which are required, e.g. public procurement or other projects. In this way, customer demands can be met and company policy can be influenced. But also, important decisions can be made within the supply chain as to which suppliers companies want to purchase from. Furthermore, the holistic analysis also serves to identify opportunities for improving the environmental characteristics of new product developments in the various phases of their life cycle. It also makes sense for marketing to make use of this tool to recognize where advantages over the competition exist and to present this to customers accordingly as well as to be able to create environmental labels or an environmental declaration for a product.7EN ISO 14044:2006 (D/E).

The main use of this method is, however, by major international organizations that want to improve the sustainability of their products.8Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. According to Jolliet et al., LCA is often used to compare the life cycle impacts of energy and emissions within a product system. In particular, the carbon footprint and greenhouse gas emissions are often mentioned as part of the ‘impacts’. The most important areas of application are therefore energy in connection with e.g. electricity or fuel as well as the building sector in connection with materials and construction and also technology, waste, recycling, and water.9Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

With regard to sustainability, the LCA is usually limited exclusively to the analysis and evaluation of the environmental impacts of product systems and thus covers only one pillar of sustainability.10Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH. However, the life cycle approach and methodologies described in ISO 14040:2006 and 14044:2006 may also be applied to the economic and social aspects of a product.11EN ISO 14044:2006 (D/E).

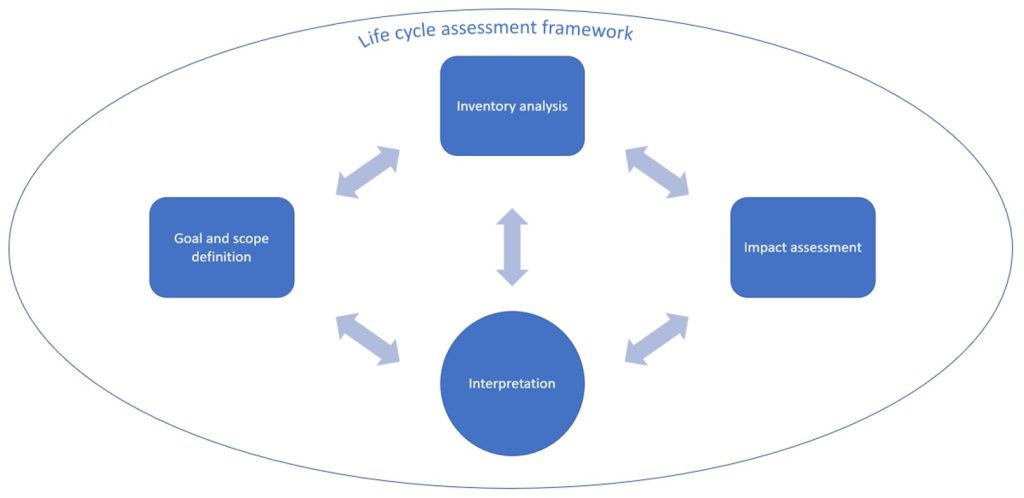

Characteristic of LCA is, as already mentioned, the analysis of the entire life cycle, hence the analysis of individual or several interconnected processes that together form a system that has a product or a service in its center. In addition to this thinking in systems, it is important to understand that the LCA evaluates the system’s function, which is decisive for the comparability of different systems or alternatives. The LCA considers systems as functional units and analyses those which perform a specific function and thus have a benefit. It thus considers the benefit of a product system as the actual standard of comparison for product comparisons, which is basically defined by its target and not just in a single product.12Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH., 13Curran, M. A. (Ed.) (2017). Goal and Scope Definition in Life Cycle Assessment. Springer, Dordrecht. While a product system’s life cycle analysis, also referred to as from cradle to grave analysis, considers all life cycle stages like raw material extraction, production, transport, usage, and disposal, the LCA study according to the ISO standards consists of four different phases. These are the goal and scope definition, the inventory analysis, the impact assessment as well as the interpretation of results which are explained in more detail in chapter 3 “Practical Implementation”.14Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

2 Background

The issue of wasting resources has become increasingly relevant in the political and everyday debate in recent decades, with the observed advance of climate change, an increased incidence of environmental disasters, and a concomitant evolution in household consumption patterns. In addition, a growing world population intensifies the already existing burden on the environment.15Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. This change in focus can be traced back to the goals that have been already outlined at the beginning of protecting the climate and nature and counteracting progressive climate change, insofar as this is possible with the given resources. It can be observed that private individuals in particular are increasingly focusing on lower consumption behavior. When selecting companies whose products are to be consumed, aspects such as socially and ecologically responsible behavior are becoming increasingly relevant.16Pawlik, V. (2021). „Bevölkerung in Deutschland nach Einstellung zur Aussage „Beim Kauf von Produkten ist es mir wichtig, dass das jeweilige Unternehmen sozial und ökologisch verantwortlich handelt“ von 2017 bis 2021 (in Millionen).“ Available at https://de-statista-com.proxy02a.bis.uni-oldenburg.de/statistik/daten/studie/182042/umfrage/kaufkriterium-soziale-verantwortung-oekologische-verantwortung/. Thus, it is important for companies to produce the products appropriately to the changing conditions, and thus to be able to respond to the changed consumer behavior.

To achieve this, the product must be viewed holistically to identify and eliminate possible weak points. From this, the strategy of Life Cycle Assessment developed, which is to analyze the product at each of its life phases in more detail.17Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. In the following chapter, the development of life cycle assessment over the past decades will be presented and thus the emergence of the ISO 14044 standard in force today will be made comprehensible.

The development observed today, however, has its origins much earlier and its beginning can be located in the 1970s and 1980s. Triggered by the decreasing number of natural resources and the observed environmental pollution, the everyday political debate and the attempt to bring about a reduction in the use of resources and the production of waste through management changes were already being made at that time. This is because both consumers and producers became aware that the situation could only be changed by targeting the core, for example, the design of the product.18Viere, T. (2019), “Introduction” in: L. Schebek et.al. (eds.), Progress in Life Cycle Assessment, Sustainable Production, Life Cycle Engineering and Management, Springer Nature Switzerland AG 2019. Industrial companies in particular were motivated by the growing interest in protecting the environment to act in a new manner and to look for new ways of producing and especially manufacturing packaging.19Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg. In each case, the focus was either on a specific point in the life cycle of the product, such as production or disposal or on a separate individual problem, such as the level of use of certain chemical substances. Although this was a logical first approach, it did not bring about the hoped-for holistic change.20Fava, J.A. (2014) “Foreword”, in: Klöpffer, W.: Background and Future Prospects in Life Cycle Assessment (LCA Compendium – The Complete World of Life Cycle Assessment). Thus, initial studies often referred to looking at the impact of packaging and the term “throwaway society” began to spread.21Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg. However, this can be recognized as the starting point of the development of an LCA methodology, which has continued to evolve and be reflected in everyday business life to this day. Thereby, it is considered one of the most widely used methods to measure the extent of a product’s impact on its environment at each stage of its life cycle and to be able to delete potential hazards.22Viere, T. (2019), “Introduction” in: L. Schebek et.al. (eds.), Progress in Life Cycle Assessment, Sustainable Production, Life Cycle Engineering and Management, Springer Nature Switzerland AG 2019. Even then, entrepreneurs and producers began to collect their observations regarding various influences on a product such as energy and resource consumption, which would later have an impact on the further development of LCA.23Fava, J.A. (2014) “Foreword”, in: Klöpffer, W.: Background and Future Prospects in Life Cycle Assessment (LCA Compendium – The Complete World of Life Cycle Assessment).

In 1990, the term “Life Cycle Assessment” was then defined as such by the Society of Environmental Toxicology and Chemistry (SETAC) during a workshop regarding the same topic. At that time, the primary objective was to define the methodology and thus lay a foundation for the subsequent analyses, which were standardized as a triangle-shaped process. In 1993, the existing framework was revised once again. The basic aim was to integrate standardized processes and the existing triangle-shaped process was not changed in its basic form, but merely expanded. From then on, it contained four components: Goal Definition and Scoping – Inventory Analysis – Impact Assessment – Improvement Assessment. In the course of the subsequent standardization through the development of the ISO standards, not many changes were made to this structure. Instead of “improvement assessment”, space was now made for “interpretation”. Final harmonization of the LCA followed and an international standardization process was initiated by the SETAC, which, however, spanned seven years until the first publication of the ISO standards in 2006 by the International Standardisation Organisation (ISO). Back then, they were all named according to ISO and supplemented by numbers, which has not changed as a naming pattern to this day. For example, one of the most widely used standards today is called ISO 14044, as mentioned earlier. These then replaced the SETAC Code of Practice and are still considered the authoritative guidelines for LCA today. Thus, although changes and extensions have been made in recent years, particularly with regard to the naming of the standards through giving them various numbers. However, the basic structure of the four phases remains unchanged to this day.24Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

However, in addition to all the positive voices and developments that life cycle analysis has undergone in recent years, critical voices are also being raised more frequently. For example, contrary to the initial intention, LCA is not equally applicable in all industries and sectors of the economy. For example, in the energy sector, a decision on the construction of a coal or gas-fired power plant is rarely made by investors considering a more detailed analysis of a life cycle assessment. And yet, it plays quite a relevant role in the scientific field of this industry.25Krewitt, W. (2007). Energiesysteme im Wandel. TATuP-Zeitschrift für Technikfolgenabschätzung in Theorie und Praxis, 16(3), 54-60. Another point of criticism is that studies are often accused of having selected a certain methodology to arrive at a previously already planned goal. This is due to the fact that for an analysis often assumptions about ratios au estimates are based. In the past, it was observed, for example, that especially in the field of marketing, the statements of the companies are made in a supportive manner and thus a promotion of supposedly more environmentally friendly products took place without this actually being scientifically confirmed.26Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg. Therefore, the results of the studies must always be treated critically and possible weaknesses must be questioned.27Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. In addition, measurements of environmental impacts such as those undertaken in ecological LCA are fundamentally challenged by the fact that environmental impacts are difficult, if not impossible, to compare. In addition, many of the risks, such as those arising from nanotechnologies or biotechnologies, are still very difficult to measure and can therefore not be integrated into the measurements, which is why it must also always be assumed that the results are ambiguous.28Rennings, K. (2008). Beabsichtigte und unbeabsichtigte Umweltfreundlichkeiten. Ökologisches Wirtschaften-Fachzeitschrift, 23(2). Overall, however, the standardization of processes in the form of ISO standards has already eradicated a large proportion of the weak points that existed in the past. However, the fundamental debate for greater standardization to make the results more comparable will probably continue in the future. This also stems from the fact that the concept is so universal and can be used in so many industries, which often have no interfaces. The problem of the “throwaway society” that has been mentioned still exists today and even if the development of LCA standards does not lead to a complete elimination of this phenomenon, the results collected can be seen as assistance in building a circular economy based on the realities.29Senft, R. (2022). Chancen der Kreislaufwirtschaft nutzen!. Tagesspiegel Background Sustainable Finance.

Often in the literature, the language is from the consideration of the Ecological aspects of LCA, as they are also primarily highlighted in this elaboration. In recent years, however, another variant has developed, the so-called social LCA. However, this is still in the early stages of development. Here, the focus is on the evaluation of the social and sociological impacts that occur within the life cycle of a product. As with ecological LCA, all phases are considered and the respective impact categories are analyzed in more detail. However, there are still many industrial branches that have not yet dealt with social LCA in more detail, and thus the results are limited to a few products. This also means that the methods researched and applied are not yet equivalent in nature and scope to those used in Ecological LCA.30Muthu, S. (2015). Social Life Cycle Assessment: An Insight (Environmental Footprints and Eco-design of Products and Processes). This can also be seen as a weakness, denying potentially influential results and their impact on future products and developments.

3 Practical implementation

Many elements are important for the successful implementation of LCA. The standards ISO14040:2006 and ISO14044:2006 provide four phases in which processes can be identified and tools and measures can be applied. In the following section, these ISO-Standards are used as best practice guidelines to provide an orderly overview of processes, measures, and tools within the framework of Practical Implementation, these are described below with the help of the four categories “Goal and Scope”, “Inventory Analysis”, “Impact Assessment” and “Interpretation”, as shown in Fig. 1. In each case, the requirements from the two categories are described. For this purpose, the specifications from the two ISO standards will methodically delimit the LCA in each case. The party commissioning the LCA, whether it is a company, an organization, or another interest group, is referred to in the following as the client.

3.1 Goal and Scope

The “Goal and Scope” phase is presented first, in which the objective is formulated and an appropriate framework with defined system boundaries is specified. According to the ISO standards, the goal of the LCA must fulfill certain criteria, whereby the intended application is presented, so that the object of the investigation is explained and it is determined whether a comparison of several products or services is considered. The client thus determines in the process of the investigation which objective is to be achieved and can thereby direct it accordingly. To be able to classify the background of the study, the reasons for conducting the study must be part of the objective. Often, special events or external influences such as legal changes are the reason for carrying out an LCA. The results obtained can, for example, subsequently support process optimization in the production area.32Umweltbundesamt, Ökobilanz. Available at https://www.umweltbundesamt.de/themen/wirtschaft-konsum/produkte/oekobilanz (2018). Furthermore, according to ISO 14040:2006, it is necessary to specify the target group addressed for the description of the objective, as well as to determine whether the results are to be published. Accordingly, it should be stated who the results of the study are aimed at and whether they will be published.33EN ISO 14040:2006(D/E).

In addition to the definition of the objective, the presentation of an appropriate scope of investigation is important in this category, so that the breadth, depth, and details of the investigation must be defined, even if these parameters can still be adjusted during the investigation. First, the product system to be investigated, and thus the life cycle of a particular product, must be defined. This is usually represented by the course of production from raw materials to the finished product so that the most important elements of physical systems are described. In each production process, the input and output factors are addressed, as will be shown in more detail in chapter 3.2, and the boundaries are completed with elementary flows. In the product system, elementary flows represent the exchange between the biosphere and the technosphere and thus symbolize either an extraction or a withdrawal in connection with the natural environment, such as geothermal energy or the emission of substances.34Forschungszentrum Jülich, Elementarfluss. Available at https://www.enargus.de/pub/bscw.cgi/d2978-2///Elementarfluss.html?op=Wiki.getwiki#:~:text=Ein%20Elementarfluss%20wird%20in%20einer,in%20die%20nat%C3%BCrliche%20Umwelt%20sein. (2022). In the ISO 14040:2006 standard, further factors to be considered for defining the system boundary are described in chapter 5.2.3. In addition, the function of the product system or, in the case of a comparative study, the function of several product systems must be classified to create a basis for the study.35EN ISO 14040:2006(D/E).

Furthermore, according to the ISO 14040:2006 standard, a functional unit is to be defined that is used as a reference value. This is an appropriate production value that represents the values to be investigated in easily calculable quantities.36Arzoumanidis, I., D’Eusanio, M., Raggi, A., Petti, L. Funktional Unit Definition Criteria in Life Cycle Assessment and Social Life Cycle Assessment: A Discussion. Springer International Publishing (2020). A system boundary is used to define the area of LCA to be investigated and based on criteria, which process modules are part of a product system. Process modules are the smallest components of the inventory analysis described in detail in Chapter 3.2 and are quantified in input and output data. A client must decide from which stage of the production process the analysis begins and where it ends.37EN ISO 14040:2006(D/E). With the help of a suitable allocation procedure, the results of co-products can be redistributed to individual products. Co-products are by-products arising during production that can also be used or represent an economic value, such as the generation of electricity and heat in a combined heat and power plant. Since the allocation is strongly dependent on subjective influences, ISO 14044:2006 recommends a system extension as an alternative. The allocation procedure is also described in more detail in chapter 3.2.38Forschungszentrum Jülich, Ökobilanzielle Allokation. Available at https://www.enargus.de/pub/bscw.cgi/d14532-2///%c3%96kobilanzielle%20Allokation.html?op=Wiki.getwiki#:~:text=Die%20Allokation%20ist%20eine%20Methodik,werden%2C%20die%20genutzt%20werden%20k%C3%B6nnen. (2022).

In the methodological framework, clients also have the option of defining the selected impact categories as well as the impact assessment and subsequent evaluation described in more detail in Chapter 3.3. Impact categories can be divided into input-related, output-related, and toxicity-related.39EN ISO 14040:2006(D/E). Further explanations of the impact categories are given in Chapter 3.3.1.

In addition, according to ISO 14040:2006, it is necessary to define the requirements for the data and their quality. Not all data are suitable for LCA and a certain quality standard should be maintained. This includes, for example, that temporal, geographical, and technological coverage and the precision and completeness of the data are defined beforehand. The exact profile of data quality requirements recommended by the ISO standard can be found in chapter 4.2.3.6 ISO 14044:2006.40EN ISO 14044:2006 (D/E). Unless sufficiently detailed information about the entire process is available, it is sometimes unavoidable to make assumptions. These should be clearly stated in advance and assumed to be constant during the assessment process. The same applies to possible restrictions and limitations, which are of particular concern in the area of impact assessment and evaluation and are therefore described in more detail in chapters 3.3 and following. In addition, a critical review of the study is possible, if necessary, to clarify whether the requirements for the LCA are fulfilled. The review is only for better understanding and increases the credibility of the study, but it does not contribute to the verification and validation of the results. To adequately present the results of the study, the client should determine in advance the type and structure of the final report.41EN ISO 14040:2006(D/E).

3.2 Inventory Analysis

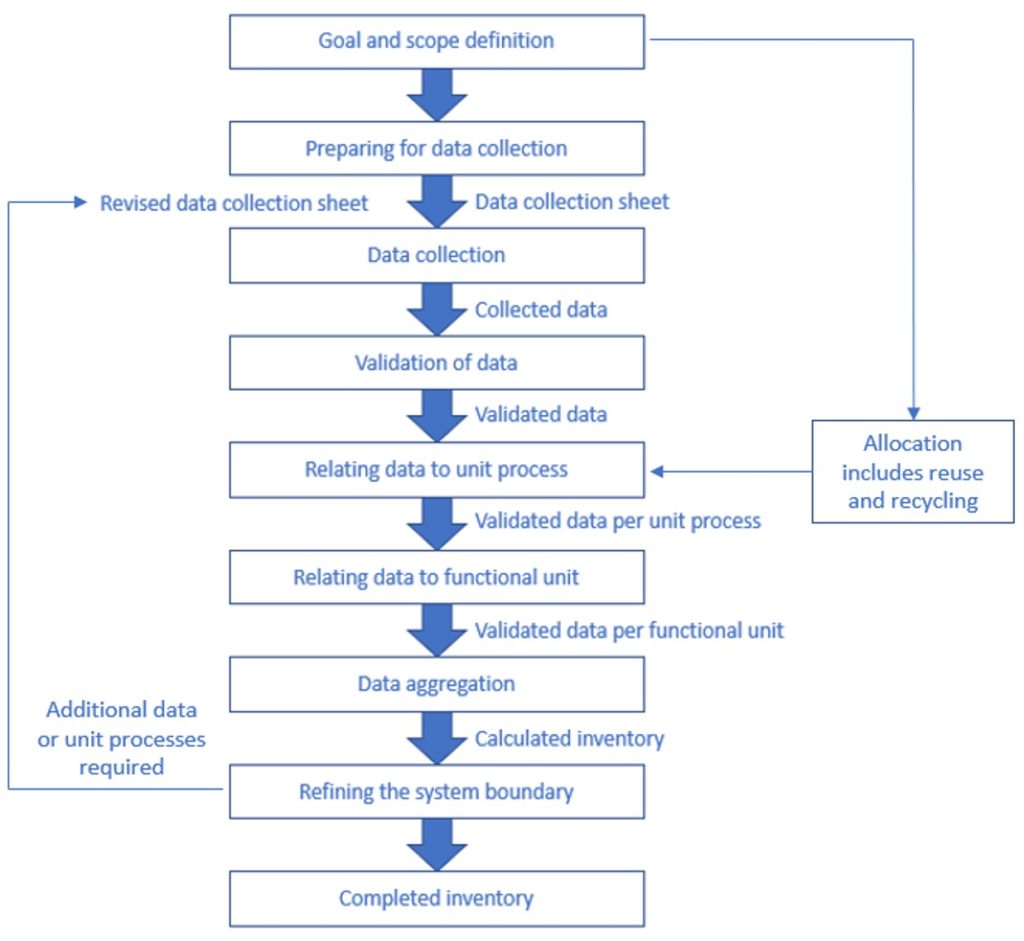

According to ISO 14040:2006, the second phase of the Life Cycle Assessment is the “Inventory Analysis”. In this iterative process, all data along the product system regarding input and output influences are compiled and quantified in the form of an inventory. The result of this analysis is an overview of cataloged flows that cross the system boundaries, which then serves as the basis for the impact assessment. During data collection, new requirements and constraints may be identified, which may result in changes in the breadth and depth of the study or even lead to the need to adjust the objective of the study.42EN ISO 14040:2006(D/E).

One method for evaluating energy flows and commitments is cumulative energy demand (KEA). According to the definition of the VDI Guideline 4600, this indicates all primary energetic expenditures that arise in the context of the production, use, and disposal of products or services and can be allocated. The KEA represents the sum of the energy expenditures in production, use, and disposal.43VDI 4600, Cumulative energy demand (KEA) – Terms, definition, methods of calculation, January 2012.

To collect data with the help of process modules, a description of the data collection techniques, as well as a clear regulation regarding the documentation of irregularities, must first be specified. For this purpose, flow diagrams are modeled that show all interrelationships and interdependencies. Subsequently, all individual processes must be described in detail about input and output factors and all flows, data, and units of each individual process must be listed.1 The process modules are then divided into main groups within the system boundaries, which reflect the influence of energy, raw materials, operating materials, and other substances. In addition, individual products, co-products, and waste, as well as environmental aspects such as emissions to air, water, and soil are also considered. Particularly for extensive surveys, a restriction in the scope of the investigation is necessary.44EN ISO 14040:2006(D/E).

Fig. 2 summarises a simplified overview of the iterative process of inventory analysis, whereby it becomes clear that the data collection up to the finished inventory is very dynamic and therefore has a corresponding influence on the system boundaries. In addition to the data collection, the data calculation is also of decisive relevance in this phase of the LCA, for which a description of the calculation techniques and explicit documentation are also necessary in advance. Validation of the collected data as well as a reference to process modules and reference flows of the functional unit are necessary in the context of these calculations. These are then summarised and compared with the system boundaries, so that additional data may need to be collected and run through the same process. When all the data has been collected and processed so that the system boundaries are defined, the inventory can be completed.46EN ISO 14040:2006(D/E).

Furthermore, within the framework of the inventory analysis, an allocation of the input and output flows and consequently also of the emissions is provided for, if several products are produced or utilized. Usually, production processes have several outputs and use intermediate products or residues as raw materials.47EN ISO 14040:2006(D/E). According to the ISO standards, an allocation must take place in three steps. First, the allocation should be avoided as far as possible, so that inputs and outputs are allocated as accurately as possible. If this is not possible, it should be checked whether the product system can be extended by functions that can be allocated to these flows. If an allocation cannot be avoided, the allocation should be made according to the physical relationships of the products or functions to each other, so that the quantitative changes of inputs and outputs within the system are related. If no physical relationship can be used as a basis, other relationships between the products or functions must be found, such as the economic value. Certain out-puts can consist partly of waste, but also of co-products so that an allocation must also be made in this respect. A basic input-output ratio is of great importance for the allocation.48EN ISO 14044:2006 (D/E).

3.3 Impact Assessment

There are two ways to conduct life cycle studies. Life Cycle Inventory-studies (LCI studies) perform an interpretation of the data based on the life cycle inventories just described. Life Cycle Assessment-Studies (LCA studies) extend this procedure by examining the environmental impact of the input and output streams collected in the inventories in a third step, the “Impact Assessment”. In contrast to mere Life Cycle Inventory studies, complete LCA studies offer the advantage of bundling the often numerous and confusing data on flows, emissions, resource consumption, and energy consumption and presenting them in terms of selected environmental impacts. In this way, it is possible to obtain more detailed and deeper insights when analyzing and comparing different products and to clearly present the advantages and disadvantages of production methods and supply chain design regarding specific environmental impacts.49Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

3.3.1 Application steps

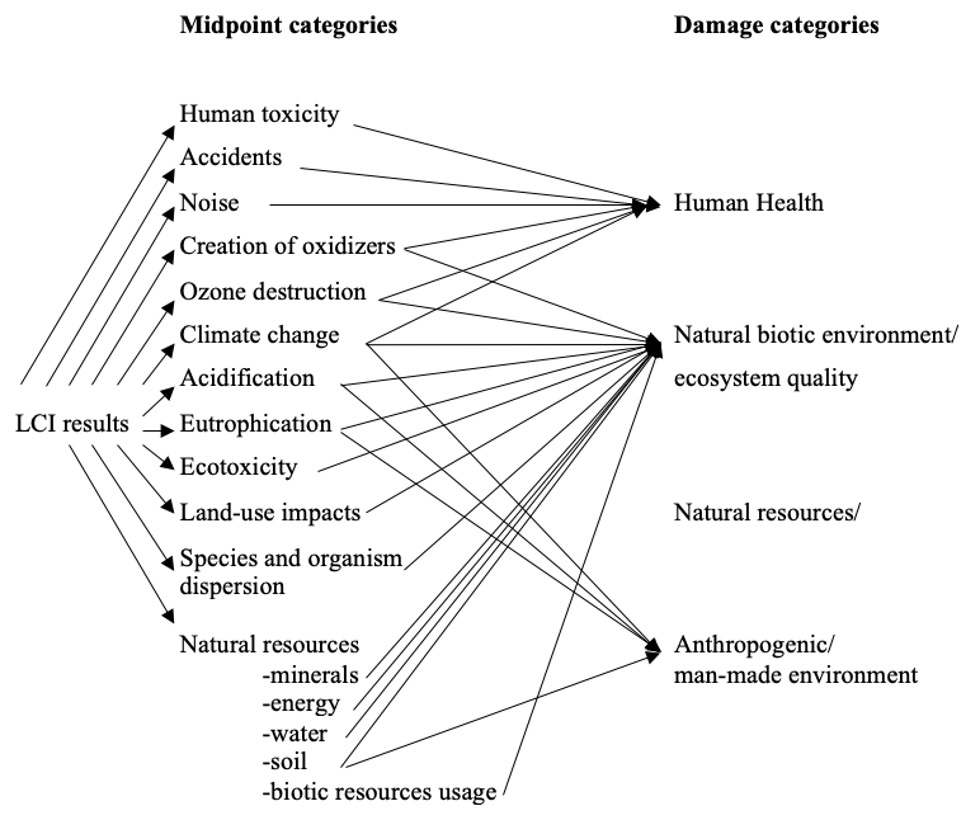

For this step to be successful in practical application, it is necessary to create a methodological framework that links the inventory data with the environmental damage. The basic principle of impact assessment is that inventory results with similar effects (such as emissions that contribute to the greenhouse gas effect) are grouped in an impact category.50Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press. These impact categories can be mid-point oriented or end-point oriented. Mid-point-oriented means that the potential negative effects are not used as the result indicator, but the substance flows summarized using characterization factors are used instead.51Curran, M. A. (Ed.). (2012). Life cycle assessment handbook: a guide for environmentally sustainable products. John Wiley & Sons. For instance, the emission of CO2 itself does not have a damaging effect, but rather the greenhouse effect and the associated increase in temperature. Each midpoint category can then be assigned to a so-called damage category in the course of an endpoint-oriented analysis. These damage categories represent the damage potential of flows in areas such as the environment or human health (see Fig. 3).52Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

For the successful application of the Life Cycle Impact Assessment, the ISO 14040:2006 and 14044:2006 as standardized best practice guidelines specify three mandatory steps in which the evaluation of the environmental impact just described is implemented: Selection, Classification, and Characterization.

Selection refers to the selection of different impact categories that represent a “comprehensive set of environmental issues”.54EN ISO 14044:2006 (D/E). The selection of impact categories (such as Global Warming or Marine Ecotoxicity) should consider individual factors such as the geographic region of the study and should also be adequately justified in a discussion.55Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterization models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht.

The classification step specifies that the results of the Life Cycle Inventories are assigned to the selected impact categories. This means that the input and output flows of the LCI-Analysis are classified based on their specific environmental impacts. For example, the consumption of fossil resources is assigned to the “Natural Resources” category, and the emission of greenhouse gases such as CO2, among others, to the “Climate Change” category.56Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

For characterization, classified inputs and outputs are evaluated regarding the strength of their influence on the respective midpoint categories. Therefore, this step is also referred to as midpoint characterization. Here, the relative weighting of emissions and extractions is specified. For example, all emissions of greenhouse gases (CO2, CH4, NO2, etc.) can be expressed as CO2 equivalent, based on the contribution of 1 kg to the greenhouse effect in relation to 1 kg of CO2. Following this, the respective impacts of the midpoint categories must be presented in the same way in terms of their relative influence on one or more endpoint categories. For example, the damage category Human Health is the sum of different midpoint impacts like Human Toxicity, Ozone Destruction, or Climate Change, in different weighting.57Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

3.3.2 Impact Assessment Method

In the practical implementation of the Life Cycle Impact Assessment, the linking of the inventory data with their specific environmental impacts along the above-defined premises happens through predefined sets or methods called Life Cycle Impact Assessment Methods or LCIA-Methods.58EC-JRC—European Commission-Joint Research Centre—Institute for Environment and Sustainability (2011): International Reference Life Cycle Data System (ILCD): Handbook— Recommendations for Life Cycle Impact Assessment in the European Context—Based on Existing Environmental Impact Assessment Models and Factors, 1st edn 2011, EUR 24571 EN. Publication Office of the European Union, Luxemburg. Since the appearance of the first LCIA method in 1984, several others have been published, which differ, among other things, in the selection of impact categories, the data processing and presentation, or the focus on a midpoint- or endpoint-based analysis.59Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterization models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht. Three of the best-known and most widely used LCAI methods are ReCiPe, Eco-Indicator-99, and IMPACT+. A study by Stavropoulos et al. (2016), which compares the three LCIA methods mentioned, shows the different focuses and results of various approaches. For example, when comparing diesel and gasoline engines regarding the three impact categories “Ecosystem Quality”, “Human Health” and “Resource Consumption”, it is noticeable that the ReCiPe method weights the impacts of the different drive systems on the category “Human Health” significantly more heavily than on “Resource Consumption”. The LCIA method IMPACT 2002+ (today IMPACT WORLD+), on the other hand, assigns the inventory input and output flows of diesel and gasoline engines to the “Resource Consumption” category with much greater weighting. Concerning the impact category “Ecosystem Quality”, the Eco-Indicator 99 method, in contrast to the other two methods, even arrives at a negative value, which would mean that any environmental threats were avoided.60Stavropoulos, P., Giannoulis, C., Papacharalampopoulos, A., Foteinopoulos, P., & Chryssolouris, G. (2016). Life cycle analysis: comparison between different methods and optimization challenges. Procedia CIRP, 41, 626-631.

Consequently, in best practice, when selecting an LCIA method, it is of high importance to thoroughly examine the individual characteristics such as the selection of impacts, time and geographic horizons, or the number of integrated flows to achieve a meaningful result.61Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterisation models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht.

3.4 Life Cycle Interpretation

The final step, which is highly important for the successful implementation and application of LCA as a tool of corporate social responsibility, is the interpretation of the results gathered in the previous steps.62Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

ISO 14044 provides a best practice guideline consisting of three steps: The identification of significant issues, the evaluation of the results based on completeness-, sensitivity- and consistency checks, and the drawing of conclusions, limitations, and recommendations.63EN ISO 14044:2006 (D/E).

Identification of significant issues:

An essential part of this interpretation step is to analyze the results of the other three LCA application steps to identify the issues and areas that are critical to the final LCA result, and to determine the environmental impacts that are most important to the study.64Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham. When identifying the significant aspects, areas from the inventory data and the impact categories should be identified that are characteristic of the respective study and thus allow relevant interpretations.65Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

Evaluation:

The evaluation of the results aims to strengthen the trustworthiness and reliability of the LCA. To this purpose, a completeness check is carried out first, which assesses the completeness of the data situation. If there are gaps in the inventory, the assessment of the results should be repeated in the sense of an iterative procedure and, if necessary, the expectations for the study should be lowered. The sensitivity check should help to assess uncertainties in the results. It analyzes how the results change when individual parameters of the study are changed. If the results change non-significantly or only in-significantly, it can be concluded that the results may not be meaningful.66Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons. The consistency check should state “whether the assumptions, methods, and data are consistent with the goal and scope”.67EN ISO 14044:2006 (D/E). Particular attention is paid to the success of establishing differences in the quality of inventory data along a product life cycle and between different product systems in line with the importance of the processes.68Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham.

Conclusions, Limitations, and Recommendations:

Following the two previous steps, the results of the study can be conclusively interpreted. The result of such an interpretation should be conclusions and recommendations that

a) respect the intentions defined in the goal setting as well as the boundaries of the study defined by the scope setting

b) are reasonable with respect to the defined functional unit and system boundaries.

In addition, the interpretation should be presented in an understandable manner and demonstrate to the users of the study the strengths and weaknesses of the latter in terms of possible limitations.69Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham.

3.5 Practical application example with the help of openLCA

In practical application, the success of the described implementation steps relies heavily on software and data. Average LCA studies require information about thousands of processes, as well as precise information about input and output flows. In addition, all these data must be linked, balanced, and accounted for.70Ciroth, A., Burhan, S. (2021). Life Cycle Inventory Data and Databases. In: Ciroth, A., Arvidsson, R. (eds) Life Cycle Inventory Analysis. LCA Compendium – The Complete World of Life Cycle Assessment. Springer, Cham.

In the following part, the LCA work process is illustrated using some excerpts with the free and well-established LCA software openLCA. The data required for the calculation, in this case, comes from the database of Greendelta, an independent engineering consulting and software development company specializing in Life Cycle Analysis.

This LCA study aims to show the life cycle process of a PET plastic bottle from cradle to gate, i.e., from the extraction of the raw materials to the filling and provision of the finished product. Fig. 4 uses the “Production of PET granulates” to illustrate how the Life Cycle Inventories are recorded with the use of the software. The output “PET granulates” with a weight of 0.065kg requires the input of PE-HD, PET and PP granules in the quantities indicated (see Fig. 4). The inputs and outputs for the preceding production of the granulates, on the other hand, are obtained by the software from the GreenDelta database.

Overall, the cradle-to-gate production of a filled PET bottle requires many processes whose inputs and outputs must be integrated into the software. Finally, this results in a process system that shows the connections between the various processes along the product life cycle (see Fig. 5).

During the impact assessment already described, the data streams summarized in the Life Cycle Inventory are evaluated based on various impact categories. Fig. 6 shows the environmental impact of the PET bottle in terms of global warming potential (see Fig. 6). The impact assessment method selected was the Re-CiPe 2016 midpoint method mentioned above (chapter 3.3.2).

To make product selection and design decisions based on the environmental impact of those products, the comparison of LCAs of different products is of high importance. Fig. 7 shows the relative comparison of PC and PET bottles based on 18 different impact categories (see Fig. 7).

3.6 Best practice in companies

Basically, as with any measure, it is important to look not only at the theoretical underpinnings but also at the realism and implementation of the theory to make an appropriate statement about its effectiveness. The following are some examples of how individual industries and their companies are implementing and using the LCA method in order to reach their sustainability goals.

Exemplary of the implementation of an end-to-end sustainability strategy that runs through all phases of the product lifecycle and has elaborated a long-term strategy is the IKEA Group. As part of its sustainability strategy, it has set itself the goal of becoming people and planet positive by 2030 and reports annually in its Sustainability Report on current progress and upcoming programs to achieve that goal. Part of this is to achieve a reduction in the climate footprint of the entire Group while increasing sales, as well as the development of a circular product design. The basis for Ikea’s effective CO2 reduction is the monitoring and bundling of input and output flows of resources and emissions in the course of extensive LCAs to analyze and improve hot spots.71IKEA (2022). Sustainability Report FY21, 2021. Available at https://gbl-sc9u2-prd-cdn.azureedge.net/-/media/aboutikea/newsroom/publications/documents/ikea-sustainability-report-fy21.pdf?rev=6d09c40ec452441091b10d9212718192&hash=1A1FDACCB00D35EE9D64428D85CA6C4E.

Another example from the textile industry is the Cologne-based company Armedangels, which has made it its corporate goal to produce clothing from organic cotton and to transform and revolutionize the fashion industry of the “fast fashion” generation. To do this, they use the LCA method to analyze their supply chains and product life cycles to produce the goods sustainably from the ground up. This is to be achieved through zero water waste, climate neutrality without the use of fossil fuels, and the elimination of toxic chemicals that could potentially enter the water cycle in the production process. They implement LCA methods as their foundation for further decision-making.72Social Fashion GmbH (2022). Armedangels Action Report 2021. Available at https://armedangels.scalecommerce.cloud/media/f0/9c/6f/1658145996/220718_Action-Report_2021.pdf. In this way, Armedangels has already been able to use and further expand its competitive advantage as a relatively young company compared to others that already exist.73Krolle, K. (2021). Wie Armedangels nachhaltige Mode auch für den Mainstream attraktiv macht. Handelsblatt. Available at https://www.handelsblatt.com/unternehmen/nachhaltigkeit/serie-klimapioniere-wie-armedangels-nachhaltige-mode-auch-fuer-den-mainstream-attraktiv-macht/27263790.html.

In addition, globally active major corporations in the automotive industry have also changed their strategy to more sustainable production in recent years, such as the VW Group. For example, the goal of sustainable mobility is integrated into the current corporate strategy ACCELERATE and is applied in the holistic transformation of product life cycles. To obtain an overview of emissions along the product value chains, VW uses a cradle-to-grave LCA approach that divides the product life cycles of individual cars into “production”, “use phase” and “recycling” to identify effective approaches for optimization.74Volkswagen (2022). Volkswagen Showroom – Nachhaltigkeit. Available at https://www.volkswagen-newsroom.com/de/nachhaltigkeit-3698.

3.7 Pros and cons of alternative measures and tools

In addition to the tools and processes used in LCA, there are other methods to measure the environmental impacts of production processes, at least in sub-segments. Life Cycle Engineering (LCE) combines different methods, including LCA, to analyze potential environmental, economic, technical, and social impacts of products, processes, and services along the value chain, so that all essential decision criteria for a sustainable orientation are considered. Another method of LCE, which is to be seen as a supplement to LCA, is Life Cycle Costing (LCC), so that above all economic aspects within process and product development are included. These factors are carried out within the same system boundaries and framework conditions as LCA, and the life cycle is also analogous. All costs of the product are included and evaluated along the value chain so that competing options can be compared, cost drivers determined and total costs of investments better estimated. Furthermore, the Life Cycle Working Environment (LCWE), which considers social aspects along the supply chain and collects the amount of work done, health and safety information, and information on the adoption of ILO humanity conventions, should be considered more as a complementary methodology.75Fraunhofer Instistut für Bauphysik, Ganzheitliche Bilanzierung. Available at https://www.ibp.fraunhofer.de/content/dam/ibp/ibp-neu/de/dokumente/broschueren/gabi/abteilungsbroschuere-ganzheitliche-bilanzierung.pdf (2013).

These two methods already show the weaknesses of LCA, as the focus is largely on ecological factors. However, ecological factors alone can never be used to make decisions along the value chain. Sustainability can only be achieved when all three dimensions, ecology, economy, and social aspects are considered in harmony.76Kropp, A., Grundlagen der Nachhaltigen Entwicklung – Handlungsmöglichkeiten und Strategien zur Umsetzung (essentials), 1. Aufl. 2019, Wiesbaden, Deutschland: Springer Gabler. (2018).

In the following, two further methods are described as examples and compared with LCA. On the one hand, there is the Design for Environment (DfE) method, in which products or services are examined for environmentally relevant aspects in design and development processes along the value chain. In this way, environmentally harmful steps can be identified in advance and avoided through alternative procedures. However, the purely qualitative method cannot undertake product-specific targeted improvement measures that are quantified in advance as is possible with LCA. Furthermore, no reliable statements can be made about the environmental profile and weak points of the individual products.77Fraunhofer Institut für Bauphysik, Umweltgerechte Produktentwicklung. Available at https://www.ibp.fraunhofer.de/de/kompetenzen/ganzheitliche-bilanzierung/methoden-ganzheitliche-bilanzierung/umweltgerechte-produktentwicklung.html.

On the other hand, there is substance flow analysis (SFA) or material flow analysis (MFA). In this system-analytical method, all material flows of a production process are recorded so that resource efficiency can be optimized and emissions and waste minimized. In contrast to LCA, this method is not internationally standardized, which is why a large number of variants arise that vary greatly in the final analysis. As a result, the results are to be evaluated more critically than with a predefined methodology. The SFA/MFA focuses on the quantities and paths of material flows and not on the associated environmental impacts.78Umweltbundesamt, Stoffstromanalyse. Available at https://www.umweltbundesamt.de/stoffstromanalyse#:~:text=Vereinfacht%20gesagt%20stehen%20bei%20Stoffstromanalysen,Umweltwirkungen%20betrachtet%20und%20bewertet%20werden. (2013). However, the results of the LCA method are much more meaningful due to the stringency of the implementation according to ISO 14040:2006 and 14044:2006 and its scope. Due to the framework conditions of the report, no other methods can be compared at this point.

4 Drivers and barriers

As any assessment tool that impacts the core business activities of a firm, there are certain firm-internal and -external drivers, stimulating the further use and development of LCAs as well as barriers, limitations, and challenges that are obliged to be overcome to guarantee a successful LCA implementation. Both are essential to take into consideration for the sake of enhancing yet existing processes in addition to minimizing risks emanating from undiscovered obstacles.

4.1 Drivers

Since corporate sustainability is present in nearly all business functions within a firm due to its nature, it affects a wide range of business activities and processes. Its omnipresence makes it essential to take sustainability into account whenever it comes to making operational and strategic decisions. Hence, LCA can work as a decision-making tool for managers of distinct departments. Additionally, the LCA offers insights into and new approaches to sustainable value-creation opportunities.79Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

Also, financial performance can enhance, since costs and risks are reduced, whereas revenues and new business opportunities are increased.80Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

There is a wide variety of potential risks, whose avoidance drives an improved sustainability performance and vice versa. Firms that implement sustainability measures appropriately are less vulnerable to risks such as resource scarcity, which can affect revenue streams, regulatory and legal risks, reputational risks in addition to market and product-related risks. For instance, eco-premiums, environmentally and/ or socially superior products, can draw new revenue streams. Besides, an outstanding sustainability performance can attract new and maintain key customers as well as potential employees and investors due to the firm’s enhanced reputation. Considering the marketing function, sustainability endeavors can result in a competitive advantage, since sustainability can function as a differentiation criterion between products within the corresponding market.81Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

Due to LCAs comprehensive analysis, all environmental impacts along the product life cycle are considered to prevent the ignorance or devaluation of urgent and undiscovered sustainability issues. Also, LCA fosters a systematic and process-oriented way of thinking among employees and managers, which accounts for a vast increase in efficiency along the supply chain. Using analytic data capturing tools, and critical assessments considering a variety of impact criteria in addition to the awareness of the interconnections of operations, LCAs contribute to a long-term, sustainable learning process as resulting efficiency.82Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

As another positive side effect, the assessment procedures not only encourage firm-internal communication but public communication about products’ environmental performances towards stakeholders using product declarations for instance.83Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons. By doing that, the pressure for other firms to release environmental product information and to enhance their overall transparency, increases extremely.

Due to the ongoing social change of mindset in terms of sustainability issues in everyday life, the impact on political decision-making becomes increasingly visible. Sustainability evolved into an essential requirement to be able to compete in the current market from a social and political perspective.84Oztemel, E., and S. Gursev. 2020. “Literature Review of Industry 4.0 and Related Technologies.” Journal of Intelligent Manufacturing 31 (1): 127–182.

4.2 Barriers

The following survey identifies diverse barriers regarding LCA’s execution using the data set of a manufacturing company in India as well as prioritizes such. To prioritize the prior identified barriers thoroughly mentioned survey utilized Grey Relational Analysis (GRA), an advanced decision-making tool as well as the Best Worst Method (BWM), a multi-criterion decision-making method for further validation.

Findings discover that the most significant barrier, hindering the business from an effective LCA execution, seems to be the lack of management support. According to the survey, it is the management’s responsibility to train its employees in terms of environmental indices in addition to providing key data sets along with their interpretation hence implementing a culture of learning within the organization by applying a different approach.85Mangla, S. K., K. Govindan, and S. Luthra. 2017. “Prioritizing the Barriers to Achieve Sustainable Consumption and Production Trends in Supply Chains Using Fuzzy Analytical Hierarchy Process.” Journal of Cleaner Production 151: 509–525. In close connection with prior, employees seem to lack education and further training regarding environmental management in general.86Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550. One possible explanation could be the result of lacking management efforts.

In addition to a lack of education, consistent sustainable development within the organization appears to require qualified expertise and specialized knowledge to effectively analyze the findings.87Ghazilla, R. A. R., N. Sakundarini, S. H. Abdul-Rashid, N. S. Ayub, E. U. Olugu, and S. N. Musa. 2015. “Drivers and Barriers Analysis for Green Manufacturing Practices in Malaysian SMEs: Preliminary Findings.” Procedia Cirp 26 (1): 658–663. This requires skilled managers with a certain bandwidth and wealth of experience in the field of the firm’s internal sustainable development processes.88Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

It is no secret that close relationships with one’s supply chain partners are considered extremely valuable for all sorts of businesses in distinct industries, which can lead to an enormous competitive advantage. Findings provide proof that a lack of team effort across supply chains hinders an effective implementation of a profound LCA when it comes to collecting essential, overlapping data.89Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550. Interpersonal relations such as collaborations and much more effective communication channels seem to be of utmost importance. A functioning system in terms of collecting and forwarding essential data additionally requires integrated feedback measures in various phases of the supply chain to be successful.90Ghazilla, R. A. R., N. Sakundarini, S. H. Abdul-Rashid, N. S. Ayub, E. U. Olugu, and S. N. Musa. 2015. “Drivers and Barriers Analysis for Green Manufacturing Practices in Malaysian SMEs: Preliminary Findings.” Procedia Cirp 26 (1): 658–663.

Since employee training, as well as the purchase of software packages and feedback devices, require a sum of financial resources to fulfill a thorough LCA, researchers found that the lack of financial capital constitutes a major obstacle to further progress in sustainability integration within an organization.91Álvarez Jaramillo, J., J. W. Zartha Sossa, and G. L. Orozco Mendoza. 2019. “Barriers to Sustainability for Small and Medium Enterprises in the Framework of Sustainable Development—a Literature Review.” Business Strategy and the Environment 28 (4): 512–524.

Having a look at a conscientious integration of clean technologies, it became substantial for firms to not only include such within their operations but also within their corporate culture, more precisely speaking of an alignment with the firms’ organizational objectives; particularly in the manufacturing sector.92Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550. In this sense, firms seem to lack integration of day-to-day LCA activities due to their resource-intensive nature and their overall complexity as well as their continuously lacking relevance. In addition to that, corporate sustainability is a matter of a long-term process, whereas most firms focus on short-term wins.93Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

The scope of the LCA, whether the firm chooses an extended version or not, impacts the effectiveness of its execution, since the former results in rather complex processes.94Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

Lots of firm-internal barriers condition themselves, such as the lack of management support, affecting the employee’s lack of education and training, and finally lacking expertise, which might affect the management’s participation in the first place.

Due to a missing, facilely applicable framework, not all businesses benefit, especially in developing countries. Yet, there is no systematic way of integrating LCA’s activities within business processes, which is feasible for each type of business regardless of its size, industry, or development phase.95Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

4.3 Overcoming barriers

Considering financial barriers, politics are required to support the integration of more sustainable business practices. This, for instance, by setting up financial institutions to easily access credit with regard to implementing an LCA. Also, banks should not only provide the credits but consult the companies in terms of potential risks when it comes to bringing the funds into play.96Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

Thus far, collaborations were essential to maintain good relationships inside the firm as well as externally but gained even more importance within the last couple of years. Firms are advised to partner up with distinct organizations focusing on the implementation of environmental practices and assisting in activities such as finance, technical knowledge, and capacity enhancements through training programs. Especially training measures are recommended to be taken externally with the help of professional, specialized agencies to save expenses in the long run. Also, claiming the services of supporting institutions dissolves the barriers of a lacking employee training, management support, and the linkage of green technologies with the firms’ strategic objectives.97Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

Technical-wise, the effective collection of data along the supply chain seems to be problematic to execute an LCA successfully. Through the establishment of statistical control, real-time data collection measures, and electronic data interchange systems, mentioned barrier can potentially be overcome.98Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

The prioritization of the detected barriers can support managers’ decision-making processes by focusing on barriers that have a big impact, hence establishing a systematical LCA barrier removing plan.99Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550. Moreover, studies propose to detect firms’ internal and external LCA drivers and align them with appropriate business priorities, which facilitates an efficient allocation of resources.100Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

Also, LCA can be utilized as a decision-making tool beneficial to managers as well as to the overall corporate sustainability context of a firm. Hence, to continuously create sustainable value and spread awareness of the corresponding issues, firms should include further environmental impact categories in their LCAs apart from the yet existing ones.101Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

References

- 1EN ISO 14044:2006 (D/E).

- 2Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 3Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH.

- 4Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH.

- 5International Organization for Standardization, About us. Available at https://www.iso.org/about-us.html (2022).

- 6EN ISO 14044:2006 (D/E).

- 7EN ISO 14044:2006 (D/E).

- 8Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 9Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 10Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH.

- 11EN ISO 14044:2006 (D/E).

- 12Klöpffer, W., & Grahl, B. (2009). Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf. Wiley-VCH.

- 13Curran, M. A. (Ed.) (2017). Goal and Scope Definition in Life Cycle Assessment. Springer, Dordrecht.

- 14Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 15Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 16Pawlik, V. (2021). „Bevölkerung in Deutschland nach Einstellung zur Aussage „Beim Kauf von Produkten ist es mir wichtig, dass das jeweilige Unternehmen sozial und ökologisch verantwortlich handelt“ von 2017 bis 2021 (in Millionen).“ Available at https://de-statista-com.proxy02a.bis.uni-oldenburg.de/statistik/daten/studie/182042/umfrage/kaufkriterium-soziale-verantwortung-oekologische-verantwortung/.

- 17Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 18Viere, T. (2019), “Introduction” in: L. Schebek et.al. (eds.), Progress in Life Cycle Assessment, Sustainable Production, Life Cycle Engineering and Management, Springer Nature Switzerland AG 2019.

- 19Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg.

- 20Fava, J.A. (2014) “Foreword”, in: Klöpffer, W.: Background and Future Prospects in Life Cycle Assessment (LCA Compendium – The Complete World of Life Cycle Assessment).

- 21Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg.

- 22Viere, T. (2019), “Introduction” in: L. Schebek et.al. (eds.), Progress in Life Cycle Assessment, Sustainable Production, Life Cycle Engineering and Management, Springer Nature Switzerland AG 2019.

- 23Fava, J.A. (2014) “Foreword”, in: Klöpffer, W.: Background and Future Prospects in Life Cycle Assessment (LCA Compendium – The Complete World of Life Cycle Assessment).

- 24Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 25Krewitt, W. (2007). Energiesysteme im Wandel. TATuP-Zeitschrift für Technikfolgenabschätzung in Theorie und Praxis, 16(3), 54-60.

- 26Kaltschmitt, M., & Schebek, L. (2015). Umweltbewertung Für Ingenieure (2015 ed.). Berlin, Heidelberg: Springer Berlin / Heidelberg.

- 27Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 28Rennings, K. (2008). Beabsichtigte und unbeabsichtigte Umweltfreundlichkeiten. Ökologisches Wirtschaften-Fachzeitschrift, 23(2).

- 29Senft, R. (2022). Chancen der Kreislaufwirtschaft nutzen!. Tagesspiegel Background Sustainable Finance.

- 30Muthu, S. (2015). Social Life Cycle Assessment: An Insight (Environmental Footprints and Eco-design of Products and Processes).

- 31EN ISO 14040:2006(D/E).

- 32Umweltbundesamt, Ökobilanz. Available at https://www.umweltbundesamt.de/themen/wirtschaft-konsum/produkte/oekobilanz (2018).

- 33EN ISO 14040:2006(D/E).

- 34Forschungszentrum Jülich, Elementarfluss. Available at https://www.enargus.de/pub/bscw.cgi/d2978-2///Elementarfluss.html?op=Wiki.getwiki#:~:text=Ein%20Elementarfluss%20wird%20in%20einer,in%20die%20nat%C3%BCrliche%20Umwelt%20sein. (2022).

- 35EN ISO 14040:2006(D/E).

- 36Arzoumanidis, I., D’Eusanio, M., Raggi, A., Petti, L. Funktional Unit Definition Criteria in Life Cycle Assessment and Social Life Cycle Assessment: A Discussion. Springer International Publishing (2020).

- 37EN ISO 14040:2006(D/E).

- 38Forschungszentrum Jülich, Ökobilanzielle Allokation. Available at https://www.enargus.de/pub/bscw.cgi/d14532-2///%c3%96kobilanzielle%20Allokation.html?op=Wiki.getwiki#:~:text=Die%20Allokation%20ist%20eine%20Methodik,werden%2C%20die%20genutzt%20werden%20k%C3%B6nnen. (2022).

- 39EN ISO 14040:2006(D/E).

- 40EN ISO 14044:2006 (D/E).

- 41EN ISO 14040:2006(D/E).

- 42EN ISO 14040:2006(D/E).

- 43VDI 4600, Cumulative energy demand (KEA) – Terms, definition, methods of calculation, January 2012.

- 44EN ISO 14040:2006(D/E).

- 45EN ISO 14044:2006 (D/E).

- 46EN ISO 14040:2006(D/E).

- 47EN ISO 14040:2006(D/E).

- 48EN ISO 14044:2006 (D/E).

- 49Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 50Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 51Curran, M. A. (Ed.). (2012). Life cycle assessment handbook: a guide for environmentally sustainable products. John Wiley & Sons.

- 52Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 53Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 54EN ISO 14044:2006 (D/E).

- 55Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterization models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht.

- 56Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 57Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 58EC-JRC—European Commission-Joint Research Centre—Institute for Environment and Sustainability (2011): International Reference Life Cycle Data System (ILCD): Handbook— Recommendations for Life Cycle Impact Assessment in the European Context—Based on Existing Environmental Impact Assessment Models and Factors, 1st edn 2011, EUR 24571 EN. Publication Office of the European Union, Luxemburg.

- 59Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterization models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht.

- 60Stavropoulos, P., Giannoulis, C., Papacharalampopoulos, A., Foteinopoulos, P., & Chryssolouris, G. (2016). Life cycle analysis: comparison between different methods and optimization challenges. Procedia CIRP, 41, 626-631.

- 61Rosenbaum, R.K. (2017). Selection of impact categories, category indicators, and characterisation models in goal and scope definition. In: Curran, M.A. (ed.) LCA Compendium—The Complete World of Life Cycle Assessment—Goal and scope definition in Life Cycle Assessment, pp 63–122. Springer, Dordrecht.

- 62Jolliet, O., Shanna S., Crettaz, P., Saadé-Sbeih, M., Jolliet, A. (2016). Environmental Life Cycle Assessment. CRC Press.

- 63EN ISO 14044:2006 (D/E).

- 64Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham.

- 65Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 66Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 67EN ISO 14044:2006 (D/E).

- 68Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham.

- 69Hauschild, M.Z., Bonou, A., Olsen, S.I. (2018). Life cycle interpretation. In: Hauschild, M., Rosenbaum, R., Olsen, S. (eds) Life Cycle Assessment. Springer, Cham.

- 70Ciroth, A., Burhan, S. (2021). Life Cycle Inventory Data and Databases. In: Ciroth, A., Arvidsson, R. (eds) Life Cycle Inventory Analysis. LCA Compendium – The Complete World of Life Cycle Assessment. Springer, Cham.

- 71IKEA (2022). Sustainability Report FY21, 2021. Available at https://gbl-sc9u2-prd-cdn.azureedge.net/-/media/aboutikea/newsroom/publications/documents/ikea-sustainability-report-fy21.pdf?rev=6d09c40ec452441091b10d9212718192&hash=1A1FDACCB00D35EE9D64428D85CA6C4E.

- 72Social Fashion GmbH (2022). Armedangels Action Report 2021. Available at https://armedangels.scalecommerce.cloud/media/f0/9c/6f/1658145996/220718_Action-Report_2021.pdf.

- 73Krolle, K. (2021). Wie Armedangels nachhaltige Mode auch für den Mainstream attraktiv macht. Handelsblatt. Available at https://www.handelsblatt.com/unternehmen/nachhaltigkeit/serie-klimapioniere-wie-armedangels-nachhaltige-mode-auch-fuer-den-mainstream-attraktiv-macht/27263790.html.

- 74Volkswagen (2022). Volkswagen Showroom – Nachhaltigkeit. Available at https://www.volkswagen-newsroom.com/de/nachhaltigkeit-3698.

- 75Fraunhofer Instistut für Bauphysik, Ganzheitliche Bilanzierung. Available at https://www.ibp.fraunhofer.de/content/dam/ibp/ibp-neu/de/dokumente/broschueren/gabi/abteilungsbroschuere-ganzheitliche-bilanzierung.pdf (2013).

- 76Kropp, A., Grundlagen der Nachhaltigen Entwicklung – Handlungsmöglichkeiten und Strategien zur Umsetzung (essentials), 1. Aufl. 2019, Wiesbaden, Deutschland: Springer Gabler. (2018).

- 77Fraunhofer Institut für Bauphysik, Umweltgerechte Produktentwicklung. Available at https://www.ibp.fraunhofer.de/de/kompetenzen/ganzheitliche-bilanzierung/methoden-ganzheitliche-bilanzierung/umweltgerechte-produktentwicklung.html.

- 78Umweltbundesamt, Stoffstromanalyse. Available at https://www.umweltbundesamt.de/stoffstromanalyse#:~:text=Vereinfacht%20gesagt%20stehen%20bei%20Stoffstromanalysen,Umweltwirkungen%20betrachtet%20und%20bewertet%20werden. (2013).

- 79Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

- 80Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

- 81Manda, B. K., Bosch, H., Karanam, S., Beers, H., Bosman, H., Rietveld, E., … & Patel, M. K. (2016). Value creation with life cycle assessment: an approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. Journal of Cleaner Production, 126, 337-351.

- 82Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 83Klöpffer, W., & Grahl, B. (2014). Life cycle assessment (LCA): a guide to best practice. John Wiley & Sons.

- 84Oztemel, E., and S. Gursev. 2020. “Literature Review of Industry 4.0 and Related Technologies.” Journal of Intelligent Manufacturing 31 (1): 127–182.

- 85Mangla, S. K., K. Govindan, and S. Luthra. 2017. “Prioritizing the Barriers to Achieve Sustainable Consumption and Production Trends in Supply Chains Using Fuzzy Analytical Hierarchy Process.” Journal of Cleaner Production 151: 509–525.

- 86Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.

- 87Ghazilla, R. A. R., N. Sakundarini, S. H. Abdul-Rashid, N. S. Ayub, E. U. Olugu, and S. N. Musa. 2015. “Drivers and Barriers Analysis for Green Manufacturing Practices in Malaysian SMEs: Preliminary Findings.” Procedia Cirp 26 (1): 658–663.

- 88Kaswan, M. S., & Rathi, R. (2021). Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. International Journal of Sustainable Engineering, 14(4), 672-685. https://doi.org/10.1080/19397038.2021.1929550.