Authors: Hillari Sahori Avendaño Vivanco, Sophia Saldanha Biondi Assumpção, March, 2025

1 Desription and History

In the last few years, the effects of climate change around the world have started affecting entire populations and cities with meteorological events of large scales. Additionally, with the pandemic, it was possible to notice how transportation could be affected concerning economic production, with an increase in fuel prices.

According to Our World in Data, transport accounts for around one-fifth of global carbon dioxide (CO2) emissions [5]. Furthermore, according to the International Energy Agency (IEA), the sector experienced the most pronounced growth in emissions in 2023, surging by nearly 240 Mt globally [6].

Those emissions were composed of road travel from passenger vehicles contributing 45.1% and 29.4% from trucks carrying freight. Aviation accounted for 11.6%. International shipping contributed an amount of 10.6%. And finally, rail travel and freight emitted only 1%, besides 2.2% of the movement of materials such as water, oil, and gas via pipelines [5].

To reduce carbon emissions it is necessary to think of new solutions to reduce those values and support the goal of holding “the increase in the global average temperature to well below 2°C above pre-industrial levels” and pursue efforts “to limit the temperature increase to 1.5°C above pre-industrial levels” [7].

The International Maritime Organization (IMO) set several regulations to control and mitigate air pollution from ships, represented as the Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) [30].

One of the solutions is the electric ship, which was first outfitted with electric power systems in the 1880s for sailing and steamships in many countries. With the transition from sail to steam as the primary propulsion method in the last quarter of the 19th century, shipbuilders experimented with a number of technologies [1].

The first steam plants used reciprocating steam engines, which were well suited to ship propulsion, as both the steam engine and propellers could be built to operate at similar speeds. However, with the advent of steam turbines, the ship propellers were initially coupled directly to these new high-speed prime movers, often with poor results [1].

The mainstream of propulsion machinery was steam turbine propulsion and later diesel engines [3]. Diesel engines took over the role of direct-drive prime movers, the need for electric transmission disappeared, and electric propulsion was rarely used until the 1980s when semiconductor technology was developed and opened up new ways of variable-speed control of electric motors [3]. This led the way for the development of two other technologies, marine reduction gears and electric propulsion systems [1]. The first one, an equipment to convert the output shaft revolutions of the main engine to those required to rotate the propeller [4]. The electric propulsion system consisted of prime movers, AC generators, power conditioners, and DC or AC propulsion motors [8].

After the end of the World War I, there was a technological race to produce ships, but to prevent this from continuing, the Washington Naval Treaty was signed in 1922, establishing number and size limits on capital ship construction. Despite the successful employment of turboelectric propulsion systems in numerous ships, geared steam-turbine drives allowed a smaller displacement ship to carry more guns and armor [1].

Turboelectric and diesel-electric systems were still used for many other vessels. Electric propulsion remained especially suitable for vessels like icebreakers, submarines, and research vessels, but geared steam-turbine propulsion became predominant for large warships, passenger ships, and many other vessel types [1].

The next technology development was the transition from steam to internal combustion engines.

Diesel and gas turbine prime movers offered numerous attractive features, including reduced manpower and maintenance workload, greater fuel efficiency, and fast start-up times. What was lost in the transition from steam plants was the ability to cross-connect between the propulsion and the now ubiquitous electric plant [1].

In the 1980s, the development of large multimegawatt motor drives enabled a resurgence in electric propulsion aboard ships, however with a different technology from the previous turboelectric systems of the early 20th century. In the earlier systems, there were two electrically isolated systems aboard, the propulsion system and the ship-service system, combined via the steam system but were electrically separate. With the introduction of the variable frequency drive to power propulsion motors, both ship service and propulsion could be powered from a common set of generators, in a concept called an integrated power system (IPS). Beginning with cruise ships and evolving to a variety of ship types as the technology improved and ship owners became more comfortable with its use, the use of integrated electric propulsion has become commonplace [1].

Nowadays, with the advent of renewable energies and the development of microgrids, a new technology is under development, and it could be possible to think of All-Electric Ships (AESs) with the IPS to provide the capabilities of power generation, distribution, and control to feed all the shipboard loads [9].

It consists of a main onboard power station that accommodates the main generators which are directly connected to the main switchboard. Generating sets are built using synchronous generators that are run at a constant speed by their prime movers. Prime movers are normally diesel engines, while high power density applications (or even low emission requirements) call for gas turbine installation [9].

There are also studies investigating the use of batteries suitable for navigation (lead-acid, nickel-metal, or lithium-ion) [10] and a high interest in the application of fuel cells in the naval industry [2].

They utilize electrical energy as their power source, converting it into mechanical energy on the propulsion system through electric motors. Their outstanding emission-reduction capabilities and more flexible interior layout are driving the development of fully electric ships [10].

2 Economic Performance

The global electric ship market size was valued at USD 7.98 billion in 2022 and is expected to grow at a compound annual growth rate of 10.9% from 2023 to 2030. The revenue forecast for 2030 is estimated to be USD 19.91 billion [19].

The capital cost of the vessel, energy cost, and engine maintenance cost of hybrid vessels are very different for electric ferries. Electric ferries have a capital cost of 15-20% greater than conventional diesel vessels, with some reporting a cost of up to 40%. This increase in capital cost is compensated by significant reductions in electric energy and maintenance costs [17].

For a single ship, the investment is estimated at 15 million euros, according to the TNO Report 2019 [29].

The total costs of ownership calculation was based on a rather safe battery price assumption of EUR 700 per kWh (2020) and EUR 450 per kWh (2030) for the Netherlands in the case study presented by [29]. There are indications that the price may go down faster than this. Operational expenses include loss of cargo space, time loss for exchanging containers, and electricity costs. Also, a potential income arising from frequency containment reserve is included, in which idle (on-shore) batteries operate in a pool to balance the electricity grid. The total revenues are estimated at 234k€ for one ship. It must be noted that these revenues are uncertain for the future and depend on many aspects [29].

CAPEX and OPEX were combined using a levelized cost of energy approach. The main components that make up CAPEX are: batteries, charging stations, onboard power electronics, and electric propulsion motors. More than 80% of CAPEX is for battery containers [29].

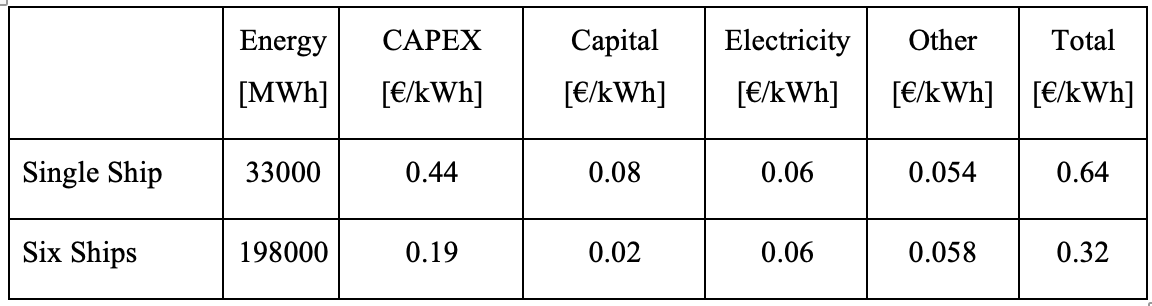

This was used to calculate the lifetime cost of one kWh electric energy delivered onboard, including investment and operational costs for the Netherlands ship called Gouwenaar. The prices per kWh are given in Table 1, generated from [29]. The kWh price for 2030 is expected to be about 25% lower due to lower battery prices. All costs are calculated without any fuel tax nor any environmental subsidies [29].

Maintenance costs for propulsion and generator engines on conventional ferries range from routine preventive maintenance to full-engine rebuilds. These costs are typically an order of magnitude less than capital or diesel costs [17].

Additional costs unique to electric vessels include electric infrastructure improvements, batteries for energy storage, and electrical system maintenance. This typically includes the electric service transformer, transmission conductors, switchgear and filters, and a rapid charging system to support vessel charging [17]. Costs related to grid infrastructure also need to be considered.

Maintenance costs for electrical systems are not substantial but should be included for maintaining charging systems, motors, drives, and generator sets. Maintenance schedules and requirements can be provided by the O&Ms to help plan and estimate these costs [17].

The battery cost is the primary constraint for cost parity of battery-electric ships with ICE ships over longer ranges. Current commercial lithium battery technologies and emerging technologies, such as solid-state batteries, are not projected to decline to this extent, given the cost of the materials used in these batteries [18].

At battery prices of US$100 kW/h, the total cost of propulsion of a battery-electric containership is lower than that of an internal combustion engine (ICE) equivalent over routes of less than 1,000 km – without considering the costs of environmental and health damages. With policy support to internalize the environmental costs of heavy fuel oil and near-future battery prices of US$50 kW/h, routes upwards of 5,000 km can be electrified cost-effectively [18].

According to [29], the levelized cost of energy (LCoE), which calculates the costs of producing one kWh, was accessed by comparing the production of one ship against six units of the Gouwenaar II ship in the Netherlands. The comparison can be seen in Table 2. Cost numbers exclude tax and profit margins.

The energy column means the amount of electrical energy made available on the switchboard of the ship over 15 years, for the capital cost, it is the interest costs over CAPEX, with linear decrease of CAPEX amount over 10 years, the electricity costs include energy price and transport and for the other, can be assumed the maintenance, frequency Containment reserve income and costs of the power connection capacity [29].

3 Ecological Performance

The International Maritime Organization (IMO), uses standard indicators to assess the performance of onboard propulsion systems. These indicators are called ‘indexes’. The ‘Energy Efficiency Design Index’, quantifies the CO2 emissions per unit of transport work (g CO2/tonne nautical mile). This index has different values depending on the size of the vessel and ship type. The ‘Energy Efficiency Operational Indicator (EEOI) is also used during the operation of the vessel. IMO regulations require that new built vessels bigger than 400 GT do not overcome these indexes, which become more demanding every five years, in line with the implementation phases of the regulation. The first reduction, made in 2015 was set to 10%, whereas the final phase requires a 30% reduction from 2025 thereafter [15]. This reduction forces the engine’s fabricators to come up with more efficient propulsion systems with time. As a result of the implementation of EEDI in 2013 to new constructed ships, it will be a reduction of among 45 and 50 million tons of CO2 in the atmosphere annually by 2020, relative to the ‘business as usual’ escenario. In 2030, the cut-in emissions will be within 180 and 240 million tons anually [26].

Most of the recent literature proposes electrical ships as the solution for reaching the ‘zero emission target’ proposed by the United Nations. However, to fully evaluate this, it is necessary to take into account the lifecycle perspective. There exist key factors that have a direct effect on whether the use of batteries on ships is beneficial or harmful. These factors are related to the primary energy sources used for the production of electricity. In developing countries, most of the electricity is generated from coal, while in contrast, in developed countries the electricity is mostly generated from renewables or cleaner sources [13]. In addition, CO2 emissions for energy production can differ from country to country. One example is given by [13], in which 1 kWh of biogas produces 3.1 kg CO2 eq. in India, whereas 1.2 kg CO2 eq. in Switzerland. European countries have the tendency of producing relatively lower emissions than countries in Asia or America.

A case study was carried out by [13], in which hybrid vessels were compared to diesel-powered vessels in a Life-Cycle Assessment (LCA). The hybrid vessels were supposed to work only with batteries, which were connected to the grid during the night when the vessels stayed at port. It is important to mention that electric ships propulsed by batteries are incompatible with large ocean-going vessels, due to the low energy density of the batteries. For this reason, the case study was applied to vessels less than 1800 DTW. In the results, it was found that vessels run by batteries whose operation zone’s primary energy was not a clean energy source have a less environmental impact than those run by diesel, as well as for those places where the main primary energy source is renewable energy. However, in the first scenario in which the vessels are connected to a grid with no clean energy source, they still have an environmental impact. The study suggests that it should be questioned if hybrid vessels are the best solution for maritime environmental protection, whose goal is to reach zero net emissions, and which the study demonstrated is not achieved with this pattern.

Another case study showed also in [13] demonstrated that for 36 different countries of all the world, the European countries, which have a lot of eco-friendly power generation, presented enhanced environmental sustainability for propulsed vessels with electric batteries than diesel fuel propulsion. Nonetheless, in Asian countries, it resulted to be less effective in the environment relative to propulsion with diesel fuel, and this is because of the power generation sources.

Another example is the study presented in [14], which focuses on comparing offshore support vessels with a standard setup (four diesel engines) and a hybrid setup, adding two batteries to the vessel’s power generation. The results of the study showed that hybrid systems reduce local pollution and climate impact. Merging batteries with combustion engines gives a 40-45% reduction in annual global warming potential in Arctic areas and an approximately 20% decrease in the North Sea. It is relevant to mention that this study was only focused on the ‘down-stream’ or ‘tank-to-wake’ performance of the vessels, whereas for a full assessment of the environmental impact the whole ‘up-stream’ or ‘wake-to-tank’ scenario must be taken into account [13].

A report investigated the impact of electrification on the whole ferry fleet in the main countries that use ferries in Europe: Italy, Greece, Germany, and the UK [20]. Norway, the country with the largest ferry fleet in Europe and one of the countries that is a pioneer in the use of this electric battery propulsion technology was not considered in the study. The conclusion of the report was that the electrification of ferries in these four countries could reduce emissions to up to 800,000 tons of CO2. The study considered shore power, hybridization, and electric routes of up to one hour. The main reason for this is that vessels emit more GHG in port, being 26% for the four countries together. An additional example is the model of the ferry ‘Pugen Sound’, designed in Sweden. This ferry produces only 25% of the exhaust of its diesel-powered counterpart [16], having substantially lower greenhouse gas emissions where there exist clean electricity grids.

A different case study which was analyzed in [21], based on the LCA and Life-Cycle Cost Assessment (LCCA) for electric vessels of different power batteries in ferries for short-sea navigation in Croatia indicates that the most sustainable option to substitute the diesel-power vessel is the electrification with a Li-ion battery, which reduces in circa 46% less CO2 emissions. This percentage can be greater if the share of renewable energy of the country gets higher in the electricity generation market. The battery technologies analyzed were Pb-acid, Ni-MH and Li-Ion battery. This study included the change of batteries in a 20-year period due to degradation and number of battery cycles in the LCA (32 times for Pb-acid, 16 times for Ni-MH and 3 times for Li-ion). As a result of the longer lifetime of the Li-ion battery and its higher energy density, it is found to be the most environmentally friendly solution. The Ni-MH is the battery with the highest emissions attributable to its manufacturing process. Regarding the LCCA analysis, the Li-ion battery results in the most cost-effective option to replace the current power system.

The paper [27], shows an analysis of the total energy use and emissions of an electric container ship, from building it to scrapping it, comparing it with a hybrid vessel and a diesel one. All three vessels are considered to have the same route and the same amount of voyages. There are two case studies: one with 120 TEU and another one with 64 TEU, both with different routes. The results for the two vessel sizes establish that the hybrid and the all-electric ship have less energy consumption and emissions per unit than the diesel vessel. In addition, as expected, the electrically powered vessel presents a more friendly behavior than the hybrid vessel. For the construction and decommissioning stages, electric ships depict more emissions as a result of the extra emissions from the batteries. Nevertheless, as in the operation stage the emissions for the electric ship are lower than the ones with the diesel vessel, the final emissions result in a better performance for the all-electric vessel.

The discussed studies which were referenced above exhibit the same conclusion: all-electric vessels produce less emissions than vessels that are powered with diesel. Nevertheless, more studies including the construction and decommissioning phases of the ships must be made, considering the recycling part of the batteries and also the primary energy production for the grid connection to charge the batteries.

It is significant to mention that even if the emissions of all-electric vessels are less, they do not comply 100% with the zero target for their whole life cycle. On the other hand, the IMO has been in charge of enhancing diesel engines over the years, establishing mandatory normatives that require the engine’s producers to design motors with higher efficiencies, which will contribute, in a lower impact than all-electric vessels, to reach the sustainable development goals proposed by the United Nations [11].

4 Social Impact

The perceived benefits of smart autonomy are well-known, as is the understanding that technology is being developed and deployed at a faster pace than the regulatory development and consensus on uniform standards. The use cases are emerging with a new trend that focuses on sustainable operations that preserve the environment, though an overview of these applications is warranted [24].

The use of innovative digitalization to support so-called smart autonomy is touted as a means to improve cost efficiency, enhance vessel safety, and relevant here, improve environmental performance through advanced robotics, data collection, and analytic processing with the assistance of artificial intelligence (AI), machine learning, or cloud computing supported by the Internet of Things. Such digital technologies aboard vessels are evolving to either augment or replace the human in the loop of vessel operations and can re-assign tasking from the human to the machine with the use of advanced sensors and cameras for “sight and hearing” with increased electronic navigation solutions that improve prediction and reliability by utilizing increasing levels of AI systems to recognize hazardous situations through these sensor inputs. This could support efficiency and resiliency and mitigate risk in cases historically attributed to human error, such as those involving fatigue, which in turn could reduce manpower and operational costs [24].

For purposes of environmental compliance, smart autonomy can purportedly support decarbonization goals by utilizing smart autonomy to optimize ship routing and fuel consumption and thus reduce environmental impacts, such as pollution and air emissions [24].

The emissions avoided will have a massive improvement on social health and environmental preservation, which day by day is getting worse with fossil fuels. This improvement is translated also into money with externality costs. The solution is especially beneficial for island communities, coastal zones, and inland waterways, where ship emissions are the main cause of human’ disorders [25].

A common issue underlying this emerging reality is the need for more widespread acceptance by the marine industry. As many early autonomous vessels have been short-run passenger and vehicle ferries, “do we trust it?” can be a question not only of public acceptance but also essential for the commercial viability of some vessels. Key approaches to addressing these concerns are the fact that autonomous vessels and automated onboard systems continue to be regulated and that they have to date operated safely [24].

Yet the industry needs to pay attention to public concern, as despite data showing increasing automation in new vehicles such as blind spot warning and radar cruise control are reducing accidents, a few accidents profiled in a national news cycle can quickly change many perceptions. Also, while human error can be reduced by replacing humans with machines, the machines were built by humans, so human error is not eliminated [24].

Given automated systems may replace humans, the highest likelihood of job loss and job transformation is faced by the low and medium-skilled workers [22]. However, the jobs do not necessarily entirely disappear. Rather, many are likely to change and possibly become remote-controlled from a shoreside control center of some kind. However, it will take a long time before automation and unmanned vessels would have a significant impact on the industry. A slower and more evolutionary shift rather than a revolution is in progress [23].

New jobs and operational challenges will likely be created within shoreside control or monitoring systems inside shoreside control centers. The level of automation of a ship may also differ during the progress of a mission depending on the operational parameters, such as local legislation and regulation and appropriate level of autonomy for certain types of traffic and waters. Education, training and job design (and the support towards the one conducting work) need to keep pace with increases in automation to ensure that the shore-side personnel is properly in- or on the loop to deal with problems that need to be solved and to avoid deterioration of skills and overreliance on the technology [23].

5 Political and Legal Aspects

In recent years, the shipping industry has been in a focus to reduce CO2 emissions. The International Maritime Organization (IMO), is the United Nations specialized agency that is responsible for the safety and security of the shipping industry, as well as for the prevention of marine and atmospheric pollution by ships. IMO’s aim support the UN sustainable development goals [11].

Since July 2011, IMO started with the first set of international mandatory measures to improve ship’s energy efficiency. In 2018, IMO adopted further regulatory measures, as the Initial IMO GHG strategy, in line with the 2015 Paris Agreement to cut greenhouse gases (GHG) emissions responsible for global warming [11].

In July 2023, the International Maritime Organization implemented the 2023 IMO Strategy on Reduction of GHG Emissions from Ships, with stronger targets for combating harmful emissions. This strategy, incorporated at the Marine Environment Protection Committee (MEPC 80), contains a better common ambition to get to net-zero GHG emissions from international shipping by or around, promising to ensure that ships start using cleaner, zero- and near-zero greenhouse gas fuels by 2030 [11].

Furthermore, IMO is aiming for at least a 20% reduction of net-zero GHG emissions by 2030 (and ideally closer to 30%), and then a 70% cut by 2040, with the hope of reaching 80%. Particularly, this 2023 IMO GHG Strategy, visualizes a decrease in carbon intensity of international shipping (to diminish CO2 emissions per transport work), as an average for international shipping, by minimum of 40% by 2030 [11]. As a result, vessel owners and builders need to design propulsion and power generation plans that reduce fuel consumption and emissions notably in the years to come.

According to the organization, the approximate GHG reduction potential for full electric vessels is between 50-90% [11]. Nevertheless, in spite of the fact that electrical propulsion is more efficient at small speeds, it has extra conversion losses of 5-15% of the propulsive power which must be taken into account. These losses are lead in electrical components such as generator, power converters, transformers and electric motors [12].

Another important regulation in the shipping industry is the International Convention for the Prevention of Pollution from Ships (MARPOL) which was adopted by IMO on November 2nd, 1973. The main purpose of the MARPOL convection is the protection of pollution of the marine environment caused by ships due to operational or accidental causes. It was implemented as a protocol in 1978 as a result of all the tanker accidents that took place between 1976 and 1977 and started to apply to all ships on October 2nd, 1983. It has been continuously modified by amendments across the years [28].

The MARPOL Convection is composed of multiple technical annexes. Annex VI, which is called ‘Prevention of Air Pollution from Ships’, was implemented on May 19th in 2005. It defines limits for the main emissions that are emitted by ships: sulfur oxide (SOx) and nitrogen oxide (NOx) emissions and forbids the purposeful discharge of ozone-depleting substances. There are certain areas, especially near ports and cities, that have stricter rules for SOx, NOx, and particulate matter with the purpose of reducing the pollution of ships. In addition, since 2011, energy efficiency measures have been required to be implemented to reduce greenhouse gas emissions [28].

Alternative policies stated by the IMO with the goal of reducing CO2 emissions include the Ship Energy Efficiency Management Plan (SEEMP) which is an operational tool to enhance the energy efficiency of a ship saving money in the process. The plan recommends the ship owners and the operators to take into consideration the new technologies and practices when looking for maximizing the operational performance of the vessels. Additionally, the SEEMP gives an approach to shipping companies when managing ships and fleet efficiency performance throughout time with the use of modern monitoring tools. The plan is composed of three parts; the first one which is dedicated to the ship management plan to improve energy efficiency, the second one for the ship fuel oil consumption data collection plan and the last one for the ship operational carbon intensity plan [31].

All the regulations that have been developed in the maritime environment, have been created after fatal accidents when the governments realized that standards must be created in order to avoid new incidents. When it comes to protecting the planet, the creation of policies was not the exception. There exist a lot of advantages as well as some disadvantages regarding the statutes made by the International Maritime Organization for the control of emissions that ships produce such as SOx, NOx and CO2.

The main advantage is that new buildings are forced to comply with the indices and policies stated by the IMO, which become stricter with time. So, new engines’ designs need to be developed to achieve this. Nevertheless, one disadvantage is that even with new designs the vessels are not reaching the zero target goal. Another advantage is that vessel’s owners are free to choose the technology that better suits them, such as the use of batteries for the propulsion of the vessel or the use of new clean fuels. More research needs to be done for all-electric vessels, as well as new policies are expected to comply with the UN goals.

References

[1] McCoy, T.J. Electric ships past, present, and future [technology leaders]. IEEE Electrification Magazine, 3(2), pp.4-11 (2015).

[2] Thongam, J.S., Tarbouchi, M., Okou, A.F., Bouchard, D. and Beguenane, R. All-electric ships—A review of the present state of the art. In 2013 Eighth International Conference and Exhibition on Ecological Vehicles and Renewable Energies (EVER) (pp. 1-8). (IEEE, 2013)

[3] Hansen, J.F. and Wendt, F. History and state of the art in commercial electric ship propulsion, integrated power systems, and future trends. Proceedings of the IEEE, 103(12), pp.2229-2242 (2015)

[4] Wartsila.com. Marine gears and gearboxes – Wärtsilä. [online] Available at: https://www.wartsila.com/marine/products/propulsors-and-gears/gears (2021) [Accessed 3 Jan. 2025].

[5] Ritchie, H. Cars, planes, trains: where do CO2 emissions from transport come from?. Our World in Data (2020) https://doi.org/10.1002/bbb.1559

[6] CO2 Emissions in 2023 – Analysis – IEA. IEA https://www.iea.org/reports/co2-emissions-in-2023 (2024).

[7] Key aspects of the Paris Agreement | UNFCCC. Unfccc.int https://unfccc.int/most-requested/key-aspects-of-the-paris-agreement (2020).

[8] Electric propulsion systems, electric drive systems. Wartsila.comhttps://www.wartsila.com/encyclopedia/term/electric-propulsion-systems-electric-drive-systems (2016).

[9] Sulligoi, G., Vicenzutti, A. & Menis, R.. All-Electric Ship Design: From Electrical Propulsion to Integrated Electrical and Electronic Power Systems. IEEE Transactions on Transportation Electrification 2, 507–521 (2016).

[10] Bei, Z.. Challenges and Solutions of Ship Power System Electrification. Energies 17, 3311 (2024).

[11] IMO’s work to cut GHG emissions from ships. Imo.orghttps://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-GHG-emissions.aspx (2015).

[12] R.D. Geertsma, R.R. Negenborn, K. Visser, J.J. Hopman. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Applied Energy 194 30-54 (2017)

[13] Byongug Jeong, Hayoung Jang, Wookjae Lee, Chybyung Park, Seungman Ha, Do Kyun Kim, Nak-Kyun Cho. Is electric battery propulsion for ships truly the lifecycle energy solution for marine environmental protection as a whole? Journal of Cleaner Production 355 (2022)

[14] Haakon Elizabeth Lindstad, Gunnar S. Eskeland, Agathe Rialland. Batteries in offshore support vessels – Pollution, climate impact and economics. Transportation Research Part D 50 409-417 (2017)

[15] Chalermkiat Nuchturee, Tie Li, Hongpu Xia. Energy efficiency of integrated electric propulsion for ships – A review. Renewable and Sustainable Energy Reviews 134 (2020)

[16] Hosseini, Y. Electric Ferries: Range & Sustainability, Explained. Candela https://candela.com/electric-ferries-range-sustainability-explained/ (2024).

[17] The Economics of Electric Ferry Vessels – Pacific Maritime Magazine. Pacmar.com https://pacmar.com/article/the-economics-of-electric-ferry-vessels/ (2015).

[18] Kersey, J., Popovich, N. D. & Phadke, A. A.. Rapid battery cost declines accelerate the prospects of all-electric interregional container shipping. Nature Energy 7, 664–674 (2022).

[19] Electric Ship Market Size, Share And Trends Report, 2030. Grandviewresearch.comhttps://www.grandviewresearch.com/industry-analysis/electric-ship-market (2022).

[20] Decarbonizing marine transport. Siemens-energy.com https://www.siemens-energy.com/global/en/home/stories/reference-green-marine.html (2023).

[21] Maja Percic, Lovro Frkovic, Tomislav Puksec, Boris Cosic, Oi Lun Li, Nikola Vladimir. Life-cycle assessment and life-cycle cost assessment of power batteries for all-electric vessels for short-sea navigation. Energy 251 (2022)

[22] Transport 2040: Automation, Technology, Employment – The Future of Work. (2019) doi:10.21677/itf.20190104.

[23] Björk, E. Social and economic impacts of Maritime Automated Surface Ships. Chalmers.sehttps://odr.chalmers.se/items/1ef48984-0c84-4c17-af26-aa0bef112ee1 (2021).

[24] Rødseth, Ø. J., Nesheim, D. A., Rialland, A. & Holte, E. A.. The Societal Impacts of Autonomous Ships: The Norwegian Perspective. in Studies in National Governance and Emerging Technologies 357–376 (Studies in National Governance and Emerging Technologies, 2023). doi:10.1007/978-3-031-24740-8_18.

[25] Makariou, E. Electrification of vessels covering small distances. Ntua.gr (2025) doi:https://dspace.lib.ntua.gr/xmlui/handle/123456789/51389.

[26] EEDI – Rational, Safe and Effective. Www.imo.org, https://www.imo.org/fr/MediaCentre/HotTopics/Pages/EEDI.aspx

[27] Ling, Guiyang, et al. Energy Consumption and Emission Analysis for Electric Container Ships. Ocean & Coastal Management 261 107505 (2025)

[28] International Maritime Organization. International Convention for the Prevention of Pollution from Ships (MARPOL). www.imo.org, 2019, www.imo.org/en/About/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx.

[29] Abma, D., Atli-Veltin, B. & Verbeek, R. P. Feasibility study for a zero emission, battery-electric powertrain for the Gouwenaar II. Repository.tno.nl https://repository.tno.nl/SingleDoc?find=UID%201163fe91-bb12-4aee-98cb-e5ad0321a57a (2019)

[30] Gilbert, P. et al. Assessment of full life-cycle air emissions of alternative shipping fuels. Journal of Cleaner Production 172, 855–866 (2018).

[31] IMO. Improving the Energy Efficiency of Ships. Imo.org, (2013) www.imo.org/en/OurWork/Environment/Pages/Improving%20the%20energy%20efficiency%20of%20ships.aspx.